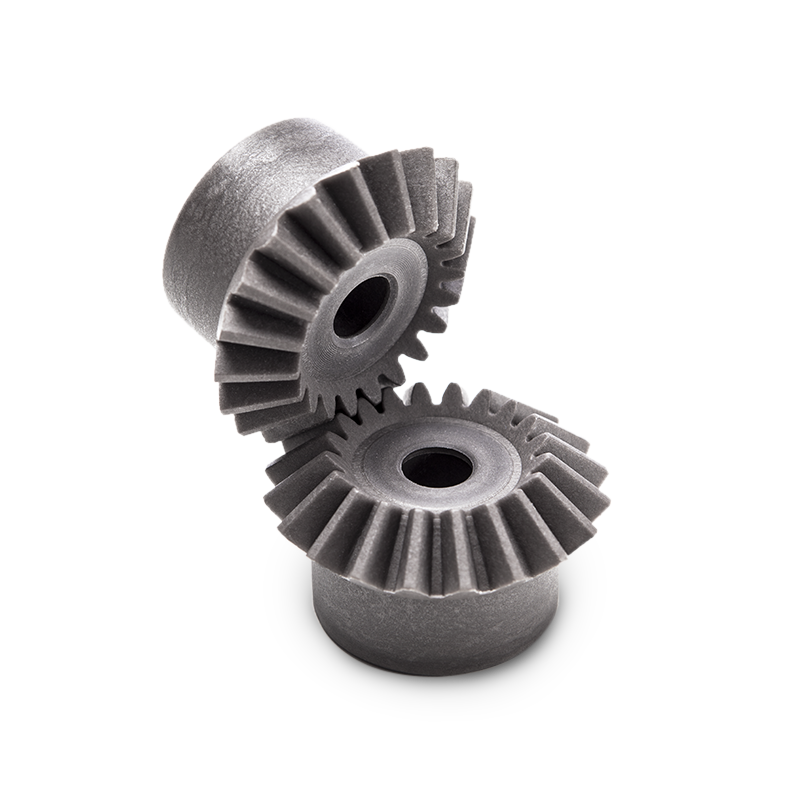

Bevel gears

Our bevel gears are made with standard teeth, suitable for use with either a second Stagnoli wheel or a steel one and, like all our products, they do not need lubricant. They are regularly supplied with a rough hole, but for minimum quantities, we supply the finished custom-designed piece by means of CNC turning (holes, keys, grains etc).

PA6 glass fiber reinforced bevel gears

| MATERIAL: | NYLON 6÷30% GLASS FIBERS |

| COLOUR: | GREY (BLUE VERSION FOR FOOD) |

| MODULE: | 1 1,5 2 2,5 3 3,5 |

| REDUCTION RATIO: | 1:1 1:1,5 1:2 1:3 1:4 |

| PRESSURE ANGLE: | 20° |

Nylon glass fiber reinforced bevel gears are used in applications that require low engine speeds and high transmissible torques; an entire blue range is available for contact with foods, whose special material complies with EU and FDA regulations in terms of various modules and reduction ratios.

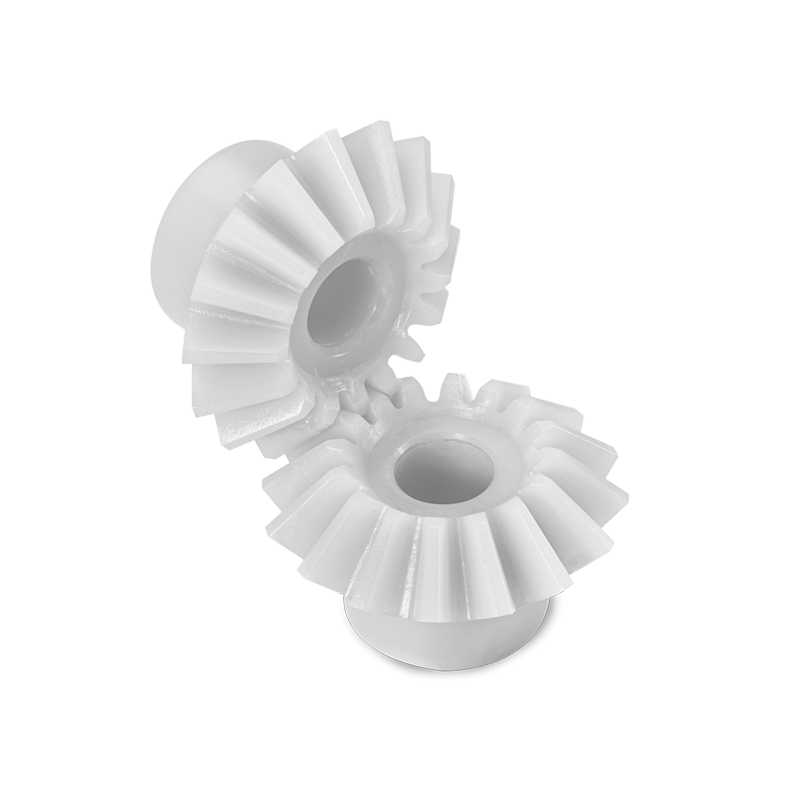

POM bevel gears

| MATERIAL: | ACETAL RESIN |

| COLOUR: | WHITE |

| MODULE: | 1 1.5 2 3 3.5 |

| REDUCTION RATIO: | 1:1 1:2 1:3 1:4 |

| PRESSURE ANGLE: | 20° |

POM bevel gears are used in applications that require high engine speeds and low transmissible torques; they also have a suitable dimensional stability mainly due to a low hygroscopicity (low water absorption) of the technopolymer, good sliding properties and wear resistance; they are physiologically inert (suitable for contact with foods) and have good resistance to a wide range of chemicals.

PK bevel gears

| MATERIAL: | POLYKETONE |

| COLOUR: | NATURAL |

| MODULE: | 1 1.5 2 3 3.5 |

| REDUCTION RATIO: | 1:1 1:2 1:3 1:4 |

| PRESSURE ANGLE: | 20° |

Compared to POM series, polycarbonate bevel gears can be used at higher operating temperatures, they guarantee greater chemical and impact resistance and thanks to an optimum surface finish they reduce the creaking that occurs when the acetal resin rotates in contact with another type of technopolymer. All this can be attributed to the chemical nature of the Polyketone, which is highly resistant to chemicals and hydrolysis, has low water absorption which leads to excellent dimensional stability, and has a great barrier effect and high toughness and impact resistance.

DOWNLOAD

THE CATALOG

WE MEET THE REQUESTS OF OUR CUSTOMERS BY PROVIDING A "FINISHED" PRODUCT.