Regulations and tests on thermoplastic gears: unity makes the difference

6 March 2023

The viability of thermoplastic gears for low loads at low transmission power is consolidated thanks to the number of advantages that plastic components offer compared to metal, such as:

- reduced weight and inertia

- reduced noise

- no external lubrication

- chemical inertia towards a number of substances, which enables use in chemically aggressive environments.

The current challenge and what the market needs most is to concentrate more on applications with high power transmission and high loads, high number of cycles, and high temperatures, which are the real limits of plastic gear resistance. We know that breaks in thermoplastics gears are caused by:

- break due to tooth distortion

- wear

- heat damage

Unlike steel gears, whose design is consolidated by standard guidelines (ISO, DIN, AGM), analytic methods, equations, and available data, the design of thermoplastic gears is more complex. Gear designers often have to deal with lack of data on plastic materials, which forces them to oversize application.

The match between theoretical calculations and experimental data according to Stagnoli

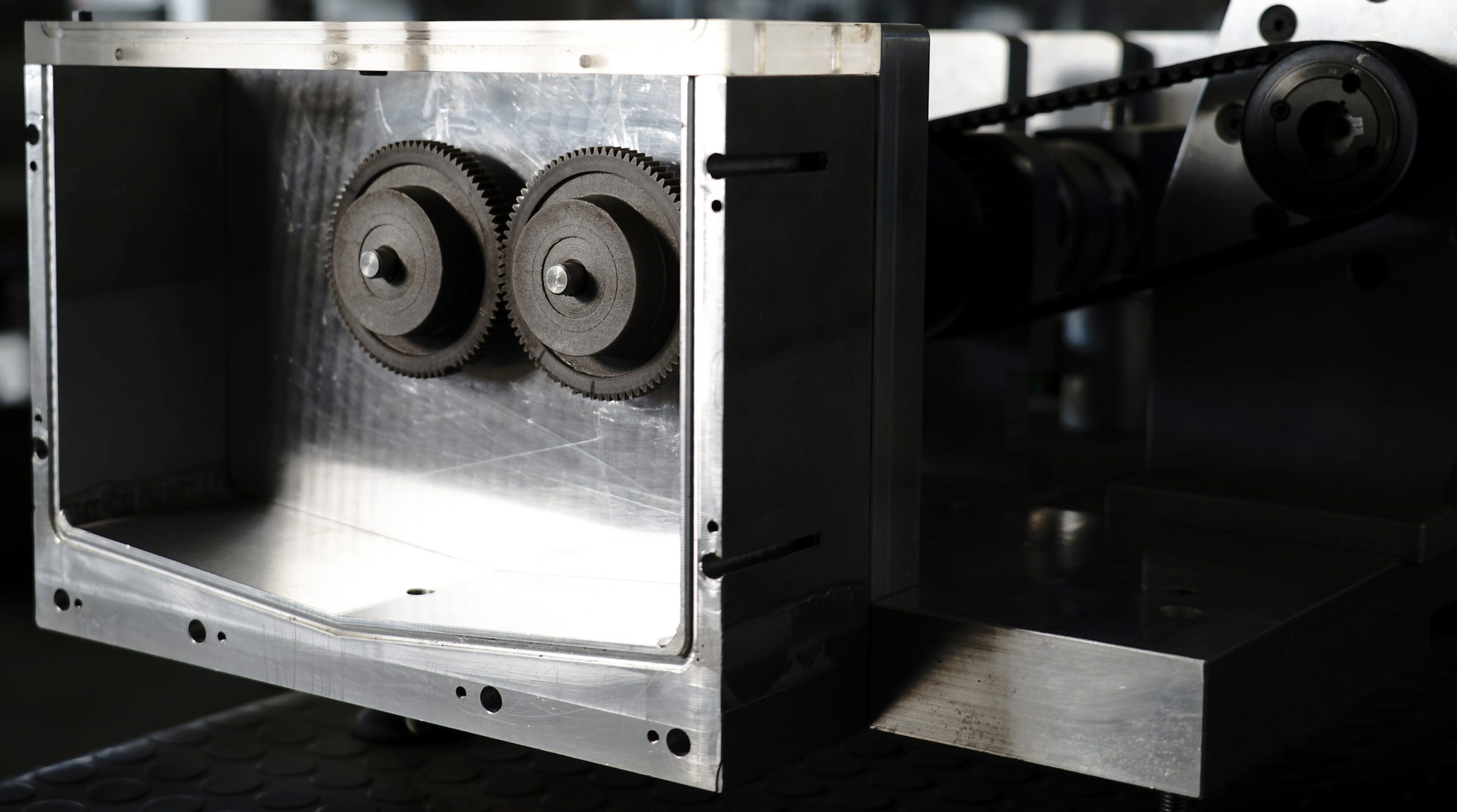

Stagnoli is a company with extensive experience in designing and producing thermoplastic gears. Thanks to our deep knowledge of the characteristics and behaviour of these components and of the new technical requirements, in recent years we have decided to guarantee the quality of our products by carrying out internal tests to provide useful data on the duration and breaking loads of thermoplastic gears.

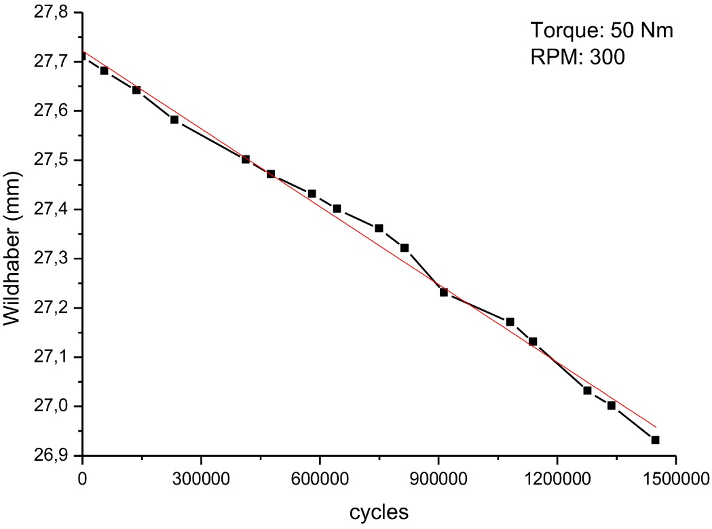

We have focused particularly on wear. The graphic below shows the Wildhaber (chord length that takes into account distance in between and the thickness of the teeth) in relation to the number of cycles made by the gear during the test. The reduction of the latter is a sign of plastic gear wear.

Performance of the Wildhaber in relation to the number of cycles.

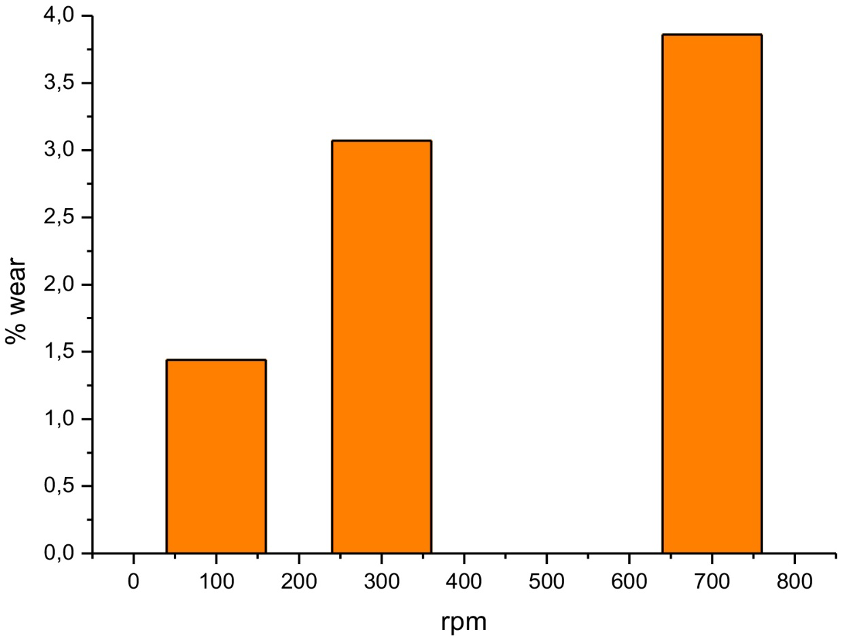

If we consider the entire gear breakage phenomenon, another consideration that can be made by observing the test results is that the percentage of wear on the sample increases as the number of rotations per minute increases. As the number of rotations increases, the weight of the wear component plays a more significant role compared to the role of the fatigue stress component.

Wear in relation to the number of rotations.

During these years, most projects we have dealt with have involved wear issues. Our competence has been essential in terms of determining the shape of the teeth, the optimisation, and the structural analysis according to the VDI2736 standard, which by now has become the international standard in the mechanic industry for plastic gears.

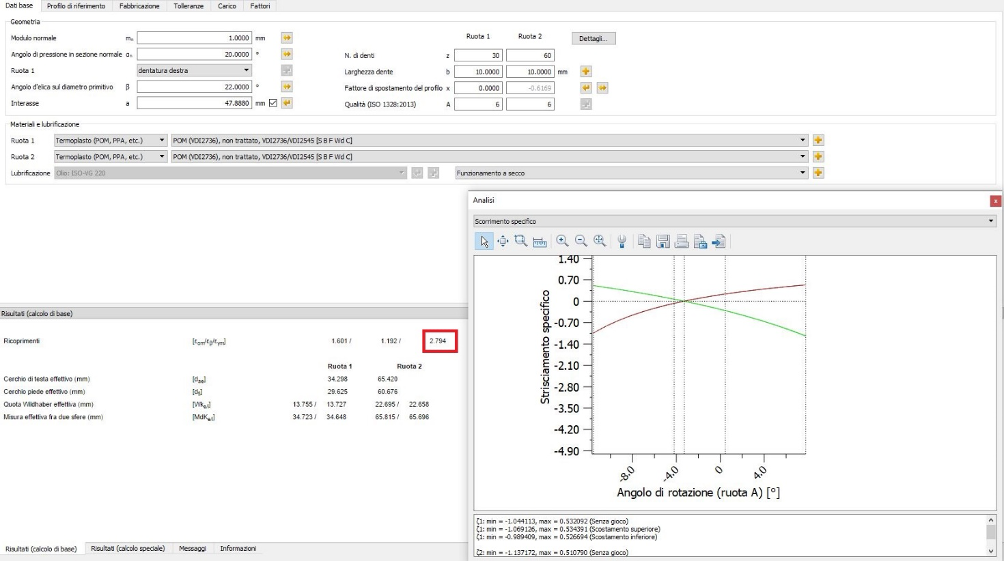

Combining the data from VDI2736 standard designs with our internal tests has allowed us to estimate the useful life of each type of gear and provide an exact answer with regard to application feasibility. Using the KissSoft software we optimise the teeth of the thermoplastic gears making corrections and adjustments aimed at increasing the coverage, resistance to wear and at the root of the teeth. An added value for our products that can really make the difference to professionals who intend to use plastic gears in their business.

Gear shape optimisation with KISSsoft software.

Would you like more information about the resistance of Stagnoli’s thermoplastic gears? Contacts us and we will answer all your questions to find together a solution to the wear of thermoplastic gears.

NEXT NEWS

31 January 2023