Components for poultry machinery: efficiency, durability and cost reduction thanks to Stagnoli technology

27 September 2024

When it comes to the poultry industry, being able to rely on components that guarantee high performance, durability and competitive costs is essential. Stagnoli has used injection moulding to develop innovative technopolymer solutions, which achieve superior results, prolong component life and improve operational efficiency. These gears have considerable advantages, notably:

- Noise reduction;

- Self-lubrication;

- Weight reduction.

Stagnoli specialises not only in the production of technopolymer gears, but also in the design and production of machinery components and spare parts for the food industry, with a focus on the precision and strength of the materials used.

High-quality materials and durability: the characteristics of Stagnoli's food machinery components

Stagnoli's gears for the food industry are manufactured from a wide range of materials, including:

- Acetal resin;

- Nylon;

- FDA-approved elastomers.

Each part is designed to stand the test of time, eliminate potential areas of contamination and be detectable in the production process.

Regardless of the size or complexity of the plastic component required, Stagnoli is able to meet every need with spare parts for industrial machines that guarantee compliance with customer specifications.

Examples of engineered components for poultry machinery

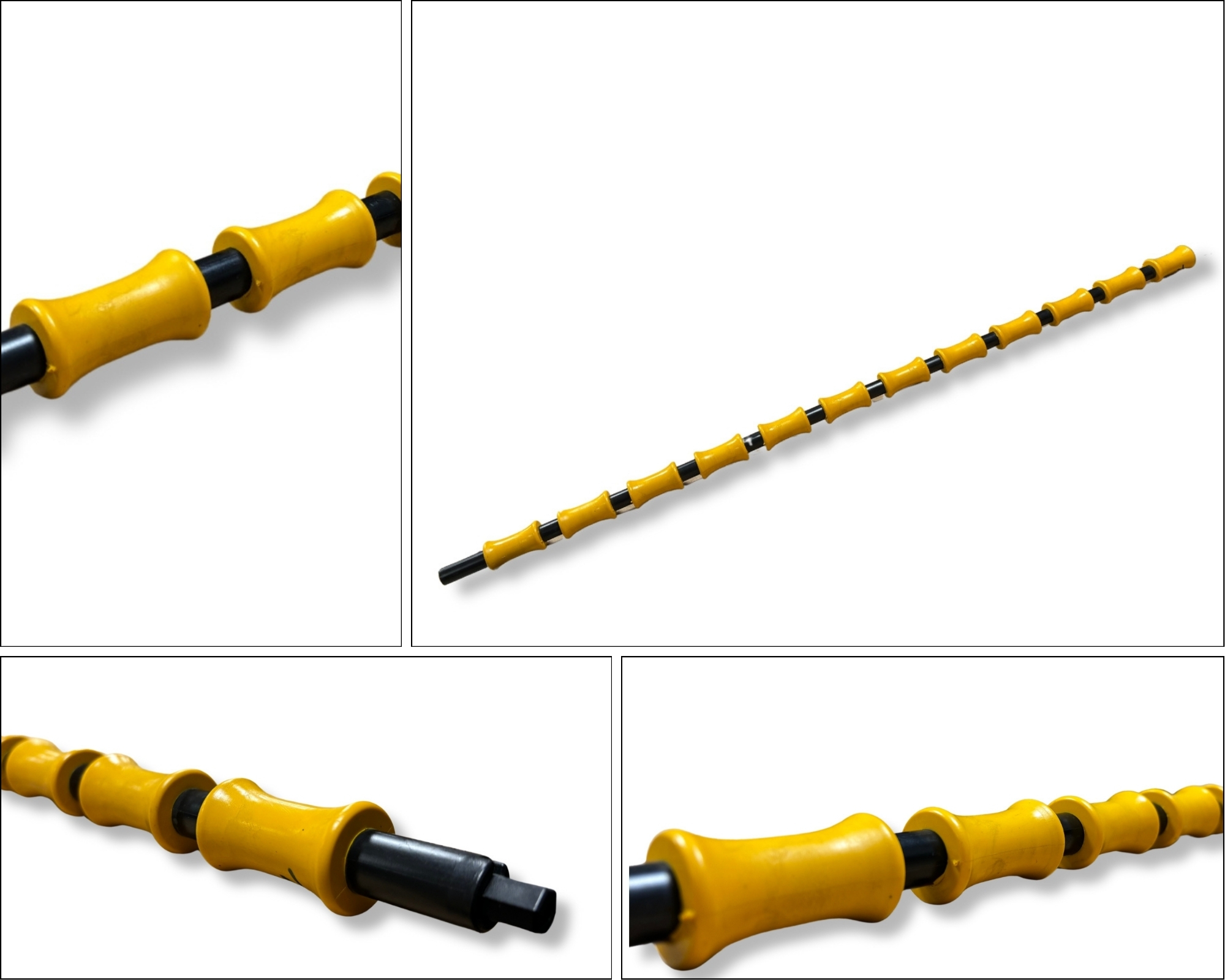

We have made some of the components for poultry machinery over the course of our long company history. Here we leave you with some pictures and information about the technopolymer gears designed and manufactured by our staff:

- Egg rollers

- Deboning equipment

- Swivel blocks for hooks

- Cones

- Trolley wheels

- Elements for cutting feet off

Stagnoli: precision and innovation in gears for the food industry

Thanks to our technological expertise and ability to develop tailor-made solutions, Stagnoli is a benchmark in the production of components for the poultry and meat processing industry. We offer efficiency, durability and cost-effectiveness to ensure optimal performance in the most demanding production processes, such as the poultry industry.

Would you like to find out more about our components for poultry and food machinery? Contact us and we will get back to you as soon as possible.