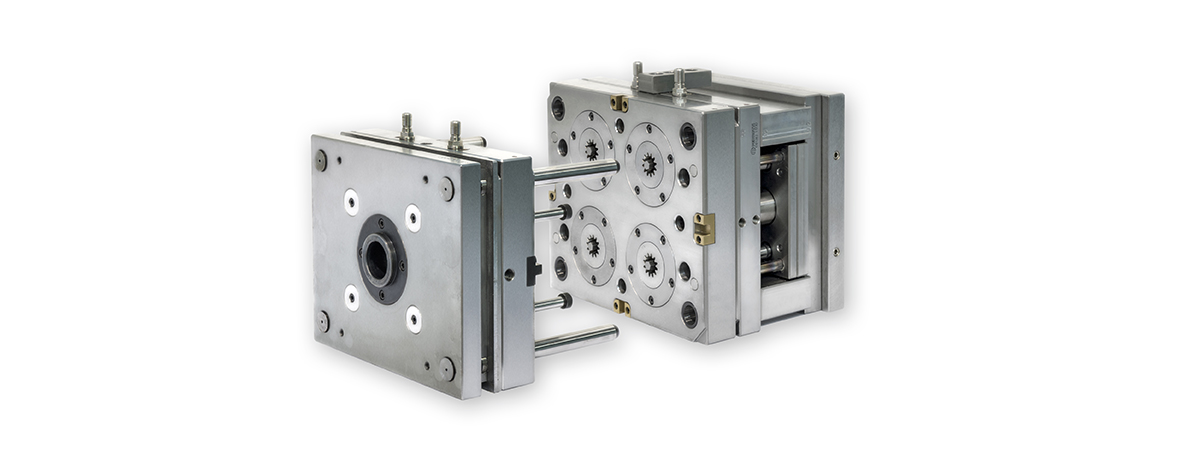

DESIGN

and CONSTRUCTION OF MOLDS

The design and construction of molds are focused on ensuring the best production of gears and transmission parts.

Our molds are internally designed, a feature that over the years has allowed us to deal with any type of request and to always find the most effective solution: from the simplest, to the most complex molds with trolleys, hot chamber or for co-molding.

The professionalism and experience of our technicians allow us, in collaboration with the customer, to always find the best solution to satisfy all needs. We consider the communication with the customer as a decisive moment in the design and production process of molds since the choice of components to be used - such as HASCO, Pedrotti or Meusburger - depend directly on the specific requests of the customer. Each phase of the design is in fact shared with the customer, in order to obtain the best possible result.

Even before the design phase of the real mold, we pay particular attention to the choice and quality of the steels we use in the execution of the mold, to guarantee durability and efficiency.

Once the material selection and mold design phase, has been completed, it is essential to proceed with a series of Moldflow simulations. These are used to prevent any type of problem and identify any criticality that may have been missed during the previous phases. In fact, these simulations allow monitoring and establishing certain critical parameters, such as injection points, cooling channels and filling and compacting values, which could negatively affect molding.

Contact us to find the best solution for your needs.

SUBMIT A PROJECT, AND WE WILL BUILD IT TOGETHER WITH YOU